When it comes to Packaging Tape usage, there are a few golden rules to remember. Our latest blog will fill you in on all you need to know!

First of all, when storing tape, we recommend keeping it in a dry location. The temperature needs to be considered too, as tape should be stored between 15°c and 25°c. Always avoid leaving tape in direct sunlight too!

Now you know the 3 golden rules of storing tape, let’s have a quick look at the different materials used.

Polypropylene vs. Vinyl Tape

Polypropylene tape (or PP tape), is the most common tape material used. It is strong, durable, and resistant to breaking, or tearing, so it is an excellent taping solution.

Generally speaking, Polypropylene tape is cheaper to buy than Vinyl tape, as it is thinner, making it a great option for companies of all sizes.

Vinyl tape is generally superior to Polypropylene tape. Due to its thickness, it is able to withstand a great deal more tension. It’s also quieter too – if you want to reduce the amount of tape ‘screeching’, consider Vinyl tape!

Now, let’s take a look at 4 different brands of tape, and their differences.

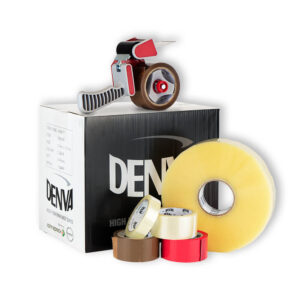

First, let’s take a look at our polypropylene Denva tape.

Our Denva tape has an acrylic adhesive, so we would recommend its use on good quality Cardboard Boxes. And to ensure you get the very best performance out of the tape, we recommend it is applied at a minimum temperature of 12°c. If you can guarantee a consistent, warm temperature, Denva could be the tape for you!

Due to the tape being ‘high tack’, it will stick to all forms of cardboard, paper, and plastic surfaces. To be honest, it will stick to almost anything!

Denva tape comes in a range of widths and lengths to suit your exact requirements! We stock both machine and hand held options too.

Please click here to view the full range.

Now let’s look at our polypropylene Texus tape

Our Texus tape has a hot melt adhesive (synthetic rubber), meaning it is constructed 3 with layers; a layer of film, the adhesive, and also a special coating that allows the tape to unwind off the roll. Unlike Denva tape, it can be used in a cooler environment, with a minimum temperature of 6°c recommended.

The adhesive is very strong, and it can be used on a variety of boxes. We would always recommend using the best quality boxes you can, but using this tape will allow you to reduce the quality if needed.

As we mentioned earlier on, please ensure the tape kept out of direct sunlight. Hot melt tape has a tendency to turn yellow in colour if exposed to UV rays.

We stock 3 types of Texus tape: Buff (brown), Clear and Clear Machine tape.

Up next, it’s our polypropylene e-tape 1

Now, many of you will know all about e-tape. After all, e-tape is one of the most recognised packaging tape brands in the market, but let’s take a look at the adhesive used.

The adhesive used on e-tape 1 is solvent (natural rubber). This offers the best tolerance to temperature, and can be used at a recommended minimum temperature of just 2°c. That’s pretty chilly!

Not only does e-tape 1 offer more resistance to the cold, but it can handle a more damp environment too.

Like Texus tape, you can use e-tape 1 on boxes of any quality. Again, we would always recommend using the best quality boxes you can, however switching to using e-tape 1 could lead to cost savings on Cardboard Boxes further down the line.

If you are looking for a tape that is strong, and versatile, look no further than e-tape 1. With e-tape, you get more tape on a roll too!

Here at Springpack we stock a huge range of e-tape. Please click here to view the range.

And last, but by no means least, it’s our V-Pro tape

The last in our line up is V-Pro. As mentioned above, this Vinyl tape offers superior quality to its Polypropylene counterparts. V-Pro uses the same solvent as e-tape 1, so it has all the same benefits, with the addition of being made from a thicker material. This really helps to increase the strength of the tape, and it can withstand more tension too.

As the tape is thicker, it also means it can work in cooler, and more damp environments. Overall it offers the best all round option, assuming cost isn’t a factor.

In summary

Buying tape can be confusing! And choosing the right tape can be difficult too. We would always recommend buying the product that is right for you, and ensuring it fits within your budget. If you are looking for a good all round tape, offering excellent value for money and quality, we would recommend you look at e-tape.

If you budget allows, you should consider a Vinyl tape, such as V-Pro. With all the same characteristics as e-tape, and more, it certainly won’t let you down.

If you really are unsure which way to turn, turn to us! Ask the experts, and talk to a Packaging Pro about your tape usage, requirements and application today.

If you’d like further information on any of the Tapes that we stock at Springpack, get in touch with the Packaging Pro’s today! You can reach us by calling 01905 457 000 or by emailing [email protected]. Don’t forget to subscribe to our YouTube channel too!