Innovative, versatile and environmentally friendly, suspension and retention packaging offers a simple and cost-effective solution to your packaging process.

Our range of Emba-Protec Suspension and Retention Packaging optimally adapts to your products and their contours like a second skin.

It is no surprise that customers expect their purchases to arrive in perfect condition, free from any dirt, damage or breakage.

Yet, with growing environmental concerns around the use of excess or plastic packaging, it can be incredibly hard to find the correct balance between keeping your products safe, and your sustainability goals in line.

This is where suspension and retention packaging comes into play, providing you with a reliable solution to protect fragile and valuable items.

In this article, we’ll explore the importance of Emba Suspension and Emba Retention packaging, their key benefits, and best practices for implementing them effectively.

Understanding Suspension and Retention Packaging

Suspension Packaging:

Suspension packaging is designed to cradle and isolate items within two layers of film. These two layers of film are surrounded by cardboard, and the two cardboard areas are pressed together.

The product is effectively “Suspended” in the middle of the package.

This means that there is no need for additional void fill materials, saving on plastic and other overall material costs. The suspended product is then loaded into a sturdy outer carton, which holds it together.

Suspension prevents products from coming into direct contact with the sides of the packaging, reducing the risk of damage from static, shocks, drops, or vibrations during shipping.

Retention Packaging:

Similar to suspension packaging, retention packaging holds the product firmly in place using a thin film. Retention packaging features a film attached to cardboard, folded in such a way that the film is kept taught around the product.

This prevents movement or shifting during transit, reducing the risk of breakage or damage.

Once again, retention packaging removes the need for additional packaging materials, such as bubble wrap. This is because all of the protection is already part of the packaging, there is no need to add additional void fill.

Benefits of Suspension and Retention Packaging:

Both Retention and Suspension packaging are particularly useful for fragile, high-value, or static-sensitive items like electronics, glassware, medical equipment, or automotive parts.

They excel in safeguarding your products from damage, which in turn increases customer satisfaction.

Cost Savings:

While investing in high-quality packaging materials might seem expensive, it can lead to significant cost savings in the long run. Reducing damaged returns, lower warranty claims, and decreasing product replacement, and return shipping costs all contribute to a considerable saving for your business.

What’s more, the reduction of product and packaging wastage will significantly increase your business’s sustainability credentials.

Eco-Friendly Option:

Our Emba products are fully curbside recyclable, meaning they are incredibly easy to dispose of and turn into something new.

To ship using Emba, no void fill materials are required. This directly leads to a reduction in the amount of packing materials required for shipping a product.

Product-Specific Packaging:

Emba packaging products are available in a huge range of shapes and sizes, making them perfect for mobile phones, automotive parts, coffee machines and more!

Types of Suspension and Retention Packaging:

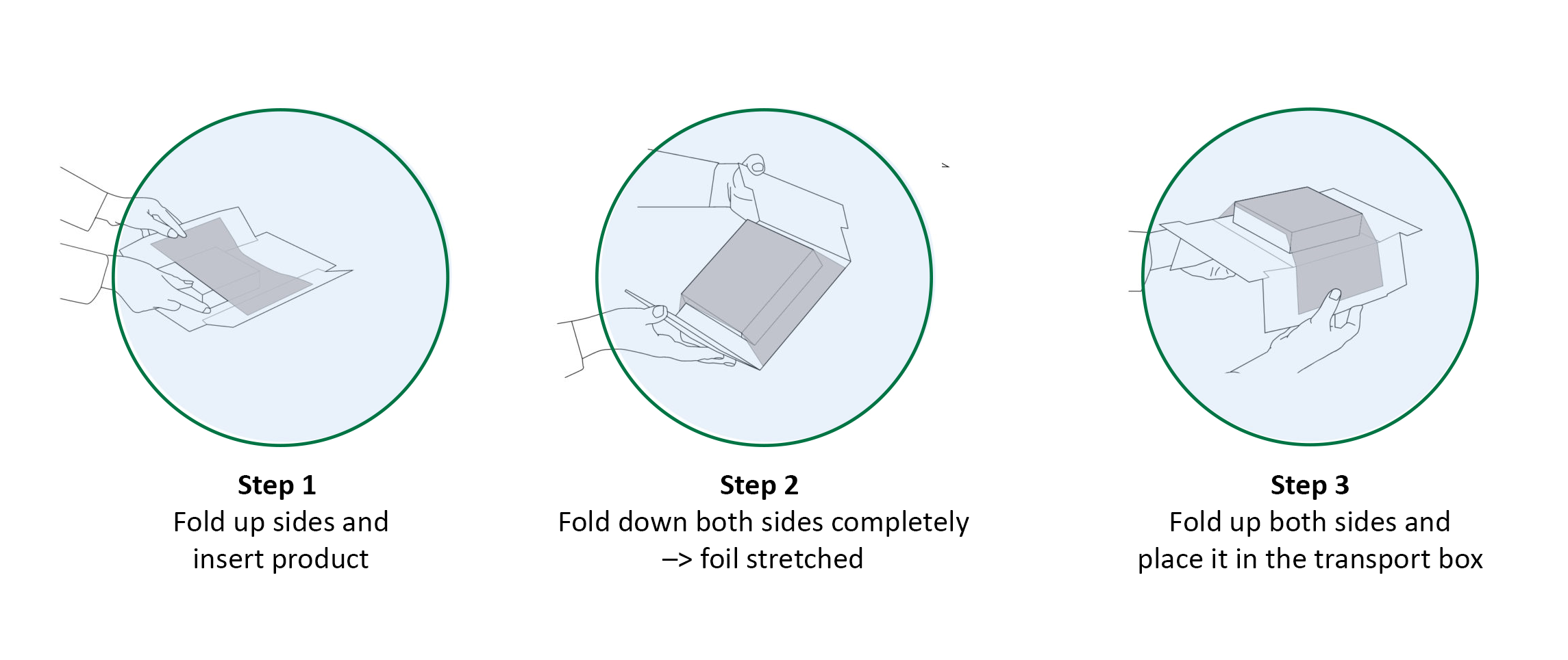

Emba Swing Suspension Packaging works to cushion your products on the top and bottom. The specially designed top and bottom trays press together surrounding your product, and when inserted into a box form the perfect protective seal.

Key Features and Benefits:

- Fast handling

- Reusable

- Maximum protection for sensitive products against shock and vibration

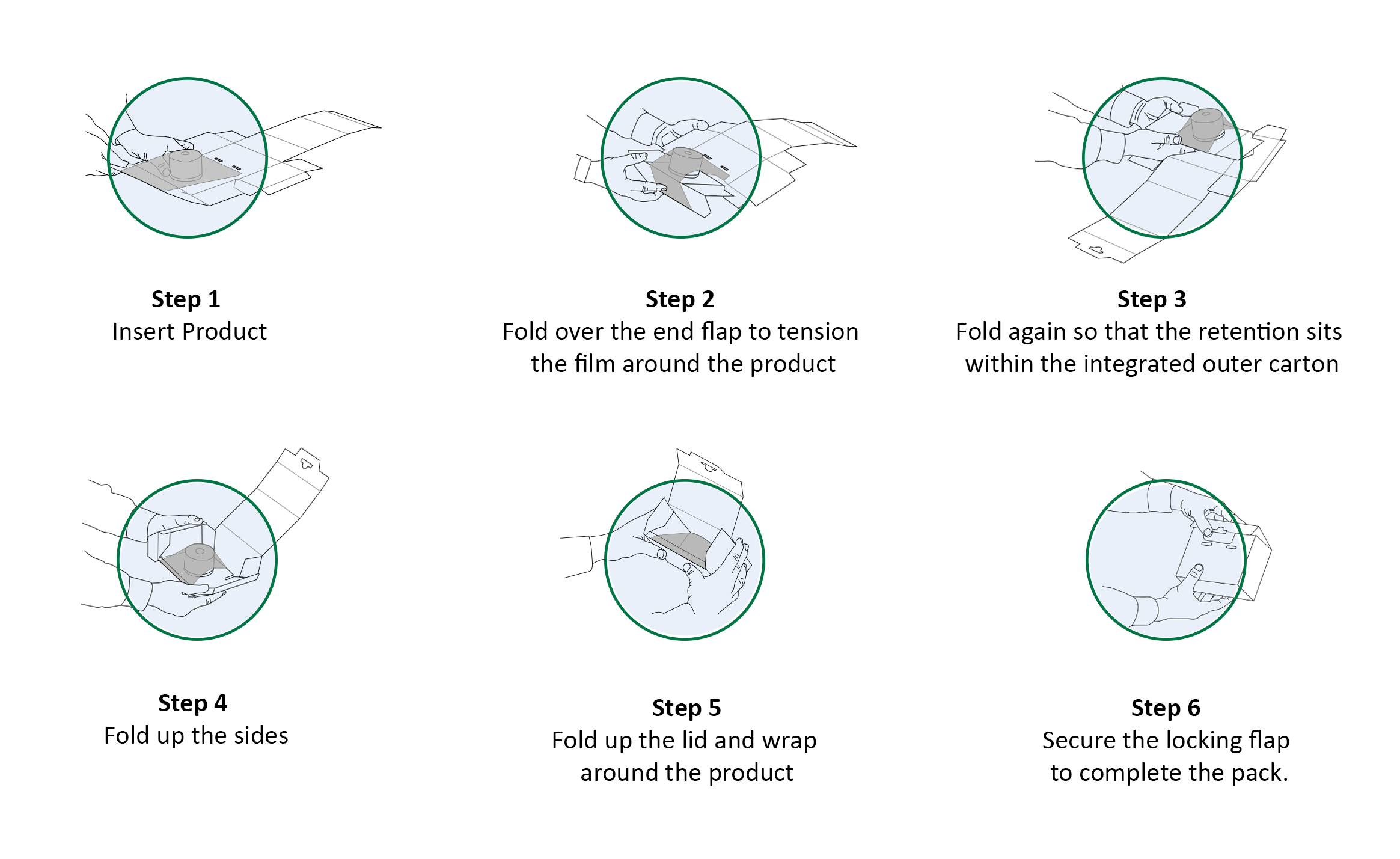

Emba Quick is a one-piece retention solution. Simply insert your product into your Emba Quick Packaging, and fold “backwards” as shown in the diagram below.

Key Features and Benefits:

- Quick assembly – ready in 10 seconds or less

- Complete packaging product – no extra outer transport box needed

- Self-adhesive closure options are available

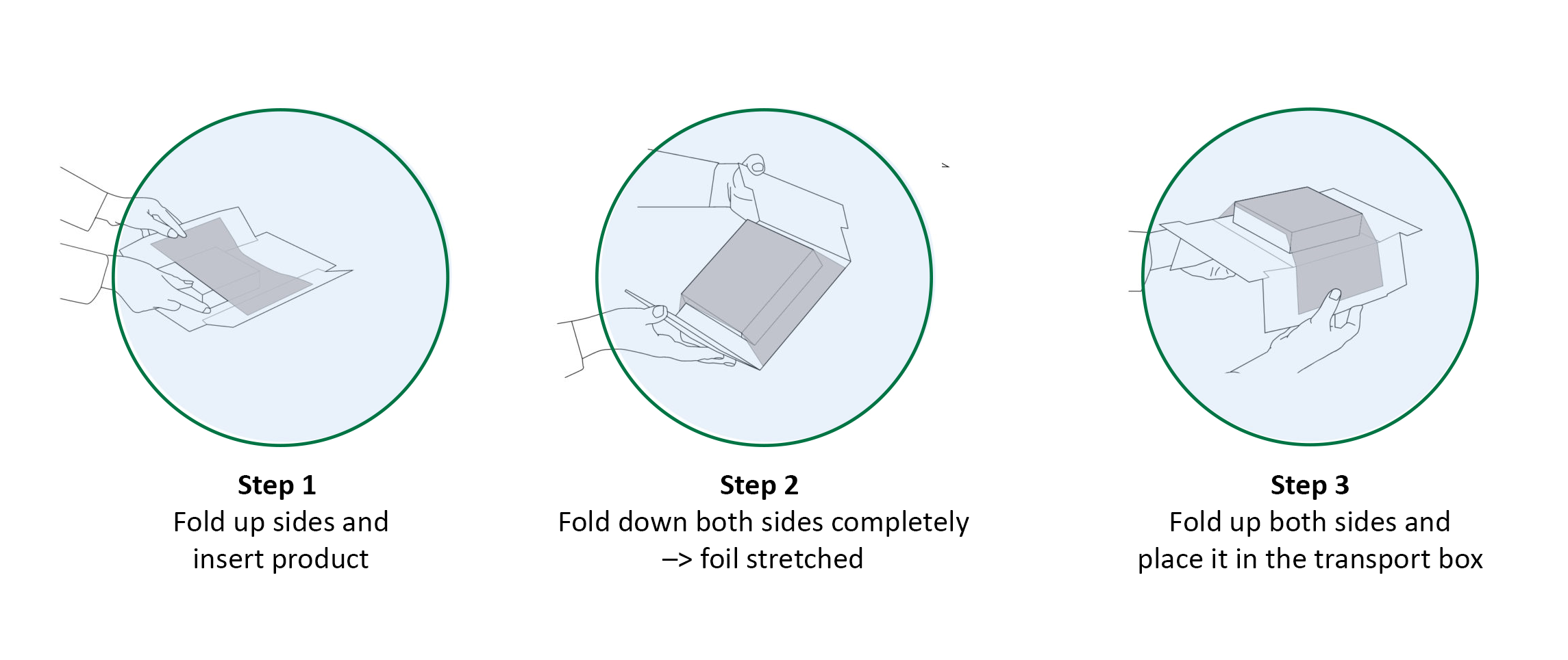

Emba Flex Retention Packaging is a two-piece packaging option. It features an internal insert and an outer box.

Simply place the product into the internal insert, and fold backwards to secure. Then load the insert into the external box.

Key Features and Benefits:

- Reduce your line up of packaging by up to 90%

- No need for adhesive – Quick fastening avoids box gluing

- Transport boxes with crash-lock base guarantee fast handling

Summary:

Suspension and retention packaging are innovations in ensuring that products reach their destination in as perfect condition as they left you in. They work by holding your product in the middle of the box, to stop your product colliding with the side of the box.

Switching to Retention or Suspension packaging can help your business save on costly returns, reduce the amount of void-fill materials required to safely ship your products, and improve your sustainability credentials.

If you’d like to learn more about how Springpack can help you streamline your packaging process, why not get in touch with one of our Packaging Experts?