What is strapping?

Strapping is a narrow material wrapped around a package or pallet and secured. Its goal is to reinforce the packaging, and prevent movement during transit.

Your choice of packaging plays a crucial role in safeguarding products during transportation and storage. The selection of appropriate strapping material is a pivotal aspect of this process.

What are the most common types of Strapping?

The most common types of strapping are polypropylene, steel, and paper strapping, and their best usage depends on several factors such as the type of product being packaged, the environmental conditions, and the desired level of security.

Additionally, selecting the right type of seals and understanding how tools like buckles, tensioners, and dispensers work in conjunction with strapping materials is essential to ensure efficient and effective packaging.

In this guide, we will explore the different types of strapping available, and their sealing solutions. If you are unsure of the best strapping for your requirements, why not get in touch with one of our Expert Team?

Polypropylene strapping

Polypropylene strapping is a popular choice for various packaging applications.

It is a lightweight and cost-effective option that is ideal for securing lightweight to medium-weight packages. Polypropylene strapping is also available in various widths and thicknesses, making it versatile for different packaging needs. It is commonly used in industries like agriculture, food, and retail.

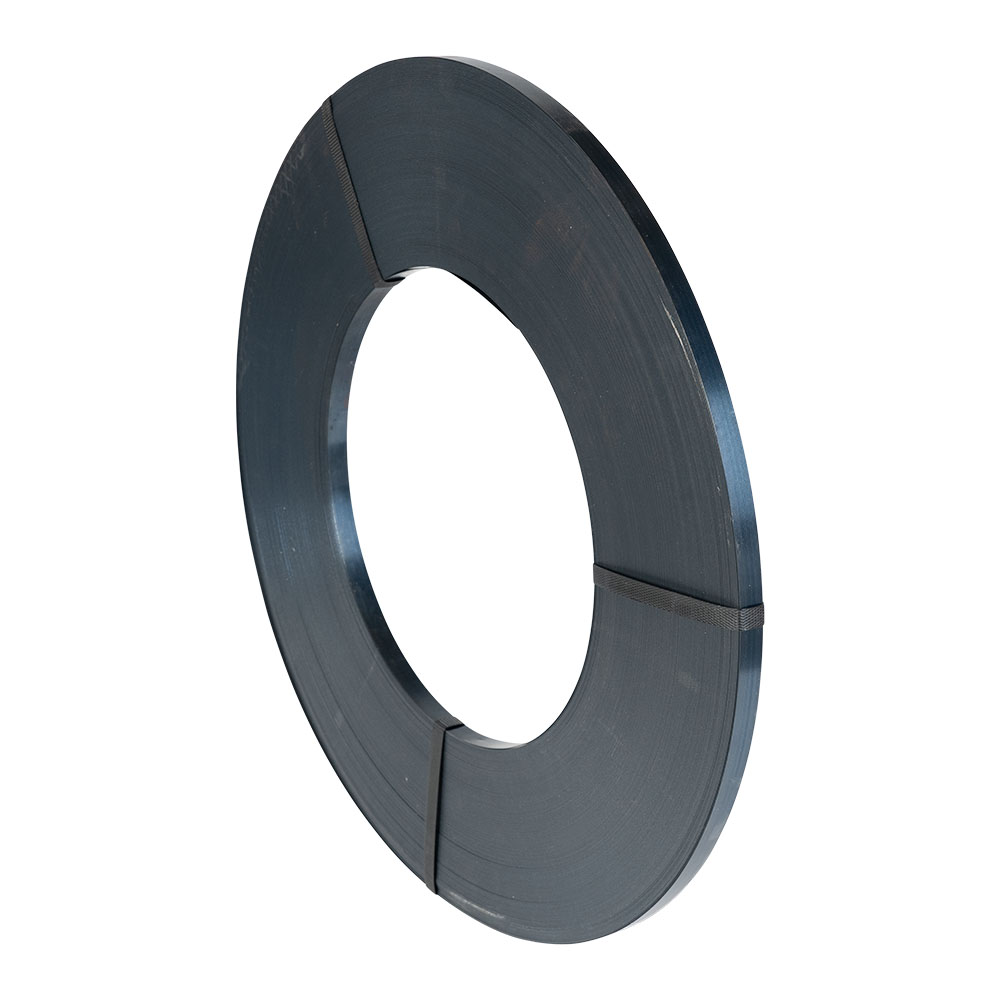

Steel strapping

Steel strapping is the heavy-duty choice for strapping materials. It is incredibly strong and durable. Steel Strapping is the preferred choice for securing heavy loads or products that require extra protection during transit.

Industries such as freight, construction, and manufacturing rely on steel strapping to prevent goods from shifting or becoming damaged. However, it’s important to note that steel strapping can be more challenging to work with due to its weight and the need for specialized tools.

Steel strapping has no give, whereas polypropylene strapping can flex slightly, it’s appropriate usage will depend entirely on what is being shipped.

Paper strapping

Paper strapping is an eco-friendly option that is gaining popularity. It is made from renewable resources and is easily recyclable, making it an excellent choice for companies looking to reduce their environmental footprint. Paper strapping is suitable for lightweight packages and is commonly used in industries transporting lightweight bulk goods.

What are Strapping Seals?

Selecting the appropriate strapping material also involves choosing the right type of seals. Seals are used to secure the ends of the strapping together to create a strong and reliable bond. There are two primary types of seals: metal seals and plastic seals.

Metal Seals

Metal Seals are often made of steel or aluminium. They are robust and provide excellent holding power.

They are often used with polypropylene or steel strapping due to their high-tension strength. Metal seals are crimped onto the strapping using special tools, creating a secure connection.

For Polypropylene strapping, they are available in semi-open or serrated.

When used with metal strapping, snap-on and lap-over are recommended.

Plastic Seals

Plastic Seals: Plastic seals are lightweight and easy to use, making them a common choice for polypropylene and paper strapping. They are applied by hand and provide sufficient strength for most packaging applications. However, they may not be as durable as metal seals for heavy-duty loads.

In the table below, you can see which buckles, tensioners and seals work together.

What tools are required to use Strapping?

To effectively apply strapping, various tools and equipment are available:

Tensioners: Tensioners are used to apply tension to the strapping material, ensuring it is securely wrapped around the package. There are manual and pneumatic tensioners available, each suited to different strapping materials, widths and volume requirements.

Sealers: Sealers are used to seal the seal once applied to the strapping.

Dispensers: Dispensers are used to manage the strapping roll efficiently. They prevent tangling and allow for smooth dispensing of strapping during the packaging process. Dispensers come in various designs, including handheld and tabletop options.

In conclusion, selecting the right strapping material for packaging is essential to ensure the safety and security of goods during transit and storage.

Polypropylene, steel, and paper strapping each offer distinct advantages depending on the specific requirements of the packaging job.

Pairing the strapping material with the appropriate seals and using the right tools, such as tensioners, buckles, and dispensers, ensures efficient and effective packaging solutions that meet the needs of various industries and environmental considerations.

Careful consideration of these factors will lead to reliable packaging solutions that protect products and minimize the risk of damage during their journey to the end consumer.

To learn more about strapping, please submit an enquiry.