Robopac Error Codes

Robopac Error Codes

From time to time we get asked to help out with an error code on a Robopac Pallet Wrapping Machine.

This handy guide has all the information you’ll ever need!

As the name suggests, an error code is a reference that the machine will display if there is an error. Now, not all error codes mean something is faulty with the machine. For example, a Robopac E60 error code means “Film Breakage”. The film may of course have torn, but it could also have run out. The simple solution is to check the film, and replace with a new one if the film has run out.

The following tables offer a detailed breakdown of the possible error codes you may see when using a Robopac Pallet Wrapping Machine.

Robopac Rotoplat Error Codes

Here at Springpack, we offer both the 508 and 708 Robopac Roboplat Pallet Wrappers, and both of the models share the same error codes. The below table details the error code, the problem, the cause, and the solution.

Error Code | Problem | Cause | Solution |

|---|---|---|---|

| E01 | Emergency mushroom-head button alarm | Emergency mushroom-head button pressed | Emergency mushroom-head button pressed |

| E02 | Carriage emergency | An obstacle has been detected along the trajectory during the spool carriage downstroke | Remove the obstacle and press the “Reset” button |

| E03 | Hand pallet truck emergency | An obstacle has been detected on the pallet loading/unloading ramp | Remove the obstacle and press the “Reset” button |

| E04 | Protection alarm | Intervention of safety barriers or open door | Remove the obstacle and press the “Reset” button |

| E30 | Inverter alarm: 1. Table 2. Carriage 3. Stretch 4. Pre-stretch 5. Presser | Power driver low power driver high over voltage max voltage under voltage hw power current over heat phase fail current max current int max parameter wrong com.Error | Contact technical support |

| E60 | “Film breakage” alarm | The film has broken or spool is finished | Insert the film or replace spool |

| E61 | Table synchronisation alarm | A fault or an obstacle is preventing the table from moving | Solve the fault or remove the obstacle and press the “Reset” button |

| E64 | Blocked carriage alarm | The carriage has stopped its travel | Remove the obstacle and press the “Reset” button |

| E65 | Blocked presser alarm | The presser has stopped its travel. | Remove the obstacle and press the “Reset” button |

| E71 | Presser position alarm | Incorrect presser position | Move the presser down and start the cycle |

| E83 | MODBUS alarm | Electronic fault | Contact technical support |

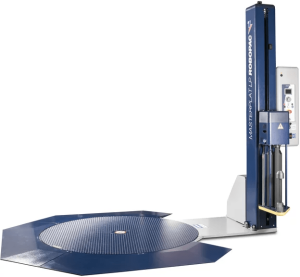

Robopac Masterplat Error Codes

The below table details the error code, the problem, the cause, and the solution for the Robopac Masterplat Pallet Wrappers.

Error Code | Problem | Cause | Solution |

| E01 | Emergency mushroom-head button alarm | Emergency mushroom-head button pressed | Reset the button and press the “Reset” button |

| E02 | Carriage emergency | An obstacle has been detected along the trajectory during the spool carriage downstroke | Remove the obstacle and press the “Reset” button |

| E03 | Hand pallet truck emergency | An obstacle has been detected on the pallet loading/unloading ramp | Remove the obstacle and press the “Reset” button |

| E04 | Protection alarm | Intervention of safety barriers or open door | Remove the obstacle and press the “Reset” button |

| E30 | Inverter alarm: 1. Table 2. Carriage 3. Stretch | Motor faults | Contact technical support |

| E60 | “Film breakage” alarm | The film has broken or spool is finished | Insert the film or replace spool |

| E61 | Blocked table alarm | A fault or an obstacle is preventing the table from moving | Solve the fault or remove the obstacle and press the “Reset” button |

| E83 | Error alarm Communication | Electronic fault | Contact technical support |

Robopac Ecoplat Error Codes

The below table details the error code, the problem, the cause, and the solution for the Robopac EcoplatPallet Wrappers.

Number of Flashes | Problem | Cause | Solution |

| 1 Flash | Inverter communication alarm | Electronic | Contact technical support |

| 2 Flashes | Plate alarm | Emergency plate pressed | Release the emergency plate and reset the machine |

| 3 Flashes | Motor alarm | Inverter overload | Remove the overload cause. Switch the machine off and then on again. |

| 4 Flashes | Table alarm | A fault or an obstacle is preventing the table from moving | Remove the fault cause. Switch the machine off and then on again |

| 5 Flashes | Film breakage alarm | Film breakage detected during a wrapping cycle | Re-join the film to the product and reset the machine) (Only available with R-Connect with film monitoring device) |

| 6 Flashes | Carriage alarm | A fault or an obstacle is preventing the film carriage from moving | Remove the fault cause. Switch the machine off and then on again |

| 7 Flashes | Pallet start alarm | If the pallet is not present on the machine, the machine will remain stationary when the CYCLE START button is pressed | Position the product on the table and start a new cycle |

Contact Technical Support:

If your error codes won’t clear, or your problem is not listed here, you may need to contact Technical Support. The team at Springpack can arrange technical support for machines purchased from Springpack, or purchased else-where.

Here at Springpack we stock a wide range of High Quality Robopac Pallet Wrapping Machines to suit all business sizes and requirements.

If you are looking to improve efficiency, and reduce your plastic use, talk to us about our range of Pallet Wrap, and how one of our Stretch Wrap Machines can help!

All of our machines come with a comprehensive warranty, and are delivered within 21 working days. All of the Robopac Machines from Springpack come with a 12 months parts and labour warranty. The turntables have a 36 month parts warranty. We’ve even put together a selection of video’s for our Pallet Wrapping Machines. Please click here to view our videos.

In addition to the machines, accessories such as ramps are available too.

Our friendly team of Packaging People are always on hand to help with any packaging requirements that you have. Don’t hesitate to contact Springpack on 01905 457 000 or click here to send us an email.