If you would like to learn more about Springpack and our services, use the form below to submit an enquiry, or get in touch with one of our packaging experts by…

The difference between Pallet Wrap and Machine Film

What is the difference between Machine Film and Pallet Wrap?

Wrapping pallets is an essential part of the packaging process for many industries, including Logistics, Manufacturing and Transport, to name a few!

The packaging world can be a tricky place to navigate. There are so many different products for similar uses, and so many uses for the same products. In this guide, we will explore the uses for a pallet wrap machine, and the differences and similarities between Machine Film and Pallet Wrap.

What is Pallet Wrap?

Pallet wrap is a type of film, usually made from plastic, that is used to wrap around a pallet to keep products secure during transit.

Applied by hand, it is wrapped around the base of the pallet and the products.

What is Pallet Wrap used for?

Pallet wrap is a plastic film that is wrapped around a pallet to secure goods in transit.

How much is a pallet wrap?

Pallet wrap is a plastic film that is wrapped around a pallet to secure goods in transit.

Types of Pallet Wrap:

Standard or Extended Core

Pallet wrap is supplied on extended or standard cores.

Standard Core Pallet Wrap is best used alongside a pallet wrap dispenser, for example, the Aero Dispenser. Whilst it can be used without a dispenser, it is a lot less comfortable to use than an Extended Core.

Extended Core pallet wrap has a longer core, meaning it can be used by hand, without needing a dispenser.

Blown or Cast

Blown and Cast pallet wrap has a slightly different manufacturing process. Both start out as resin pellets, which are fed into a machine. Cast Pallet Wrap is then fed across cooled rollers and solidifies, whereas blown has adhesive added and air blown through it.

A key difference (and a great way to tell which type of pallet wrap you are using!) is the transparency of the film. Cast film is very transparent, due to the manufacturing process. All the particles of film are facing the same way, which allows for the extra stretchiness of the film. Blown on the other hand is comparatively a little cloudier than cast film because the added air blown through it means the particles are not lined up smoothly, causing the cloudiness.

Both blown and cast wraps are available in a wide range of lengths and thicknesses to suit your individual needs. If you’re not sure which type of hand pallet wrap would be best, why not contact our Packaging Experts?

Cast Pallet Wrap is a popular choice of pallet wrap and is used by around 70% of all hand pallet wrap we sell. It is very stretchy so that it can be pulled tighter on the pallet. However, it’s important to remember that cast pallet wrap can stretch after it has been applied, this usually isn’t an issue, but is a good thing to consider if you’re shipping heavy goods.

Cast pallet wrap is also a lot quieter to use than the blown alternative, this is because it has less “Tackiness”, so doesn’t stick to the roll as much.

Blown Pallet Wrap has a lot of cling compared to the cast, due to added adhesives and being blown during the manufacturing process.

In transit, it is a lot more resistant to stretching after application, because the random alignment of particles and the added adhesive keep it taught. It’s important to note, it is slightly “cloudier” than cast pallet wrap, though it is still translucent, and you can see products that are on the pallet.

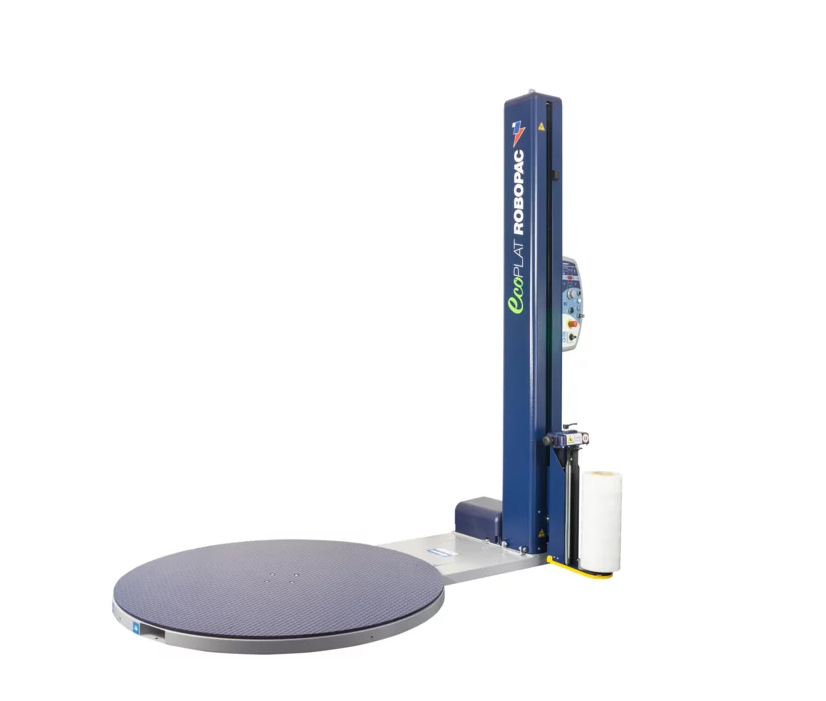

What is Machine Film - Also known as Machine Pallet Wrap

Machine film is a type of pallet wrap designed for use with pallet wrap machines like a Robopac, (also known as pallet stretch wrappers). Robopac Pallet Wrapper machines can often reduce costs, save your business time, and are an essential tool to many warehouses.

At Springpack, we offer two types of Machine Film – Simply Eco and Armour Wrap.

Simply Eco Machine film offers up to 250% stretch, contains a minimum of 30% recycled content, and is available in thicknesses from 25 to 12 microns.

Armour Wrap Machine Film is Springpack’s flagship machine film. With up to 330% stretch, it is available in thicknesses from 15 microns down to 9 microns. Armour Wrap harnesses the power of nanotechnology films. It is made from microscopically thin layers, which give Armour Wrap its unparalleled strength and durability, even down to the thinnest film.

Time and time again, Armour Wrap has improved the cost efficiency of pallet wrapping for Springpack customers, whilst offering improved load stability, and reductions in plastic waste. Armour Wrap rolls contain a longer length of wrap than other rolls, due to how thin it is!

Does the micron of Pallet Wrap Matter?

Absolutely! Though every business’s packaging needs are different, it can be tricky to create one-size-fits-all advice when it comes to down gauging. If you’re researching down gauging, why not get in touch with one of our packaging experts? We offer free packaging reviews nationwide!

It’s a good thing to note, however, that down gauging has some serious benefits that you might not expect.

A pallet that is wrapped with 5 layers of a 25-micron film (125 microns when layers are taken into consideration) can be just as stable as one wrapped with 7 layers of a 12-micron film. Whilst yes, there are two more layers, these extra layers can offer better load containment, whilst reducing the overall plastic needed to wrap your pallet

Things to consider when down gauging:

Increasing your load stability reduces damage. A few extra passes with a thinner wrap can improve load stability.

A thinner wrap can offer more flexibility, as you’re not over-wrapping lightweight pallets in with heavy-duty wrap.

A thinner micron roll often has a longer length of wrap, meaning fewer roll changes.

Using less plastic is better for your pocket, and the planet and minimises the amount of Plastic Packaging tax you will need to pay.

What is a Pallet Wrap Machine?

A Pallet Stretch Wrap Machine is a piece of machinery used in a warehouse to quickly wrap pallets.

Robot pallet wrapper machines can often be preprogrammed with a range of settings, based on the load they are wrapping, so can adjust the way they wrap, and their stretch accordingly. A pallet wrap machine, such as a robopac is a great way to ensure consistency in your warehouse operation.

Switching to a pallet wrap machine can also be a huge benefit to your staff, as it reduces risk of repetitive strain injuries from constantly wrapping pallets.

Who are Springpack?

At Springpack, our Packaging Experts really know their Pallet Wrap Machines from their Pallet Wrap Dispensers (that’s a convoluted way to say – We know our stuff!)

Experts in packaging for 50 years, Springpack h as a solution for any packaging problem, and our team are here to help.

We offer next day delivery around the UK – and same day for selected WR postcodes. This means even if you’re low on storage, your packaging doesn’t have to suffer, you can take advantage of our UK wide delivery service.

One of Springpack’s core values is to protect the environment. We have been Carbon Neutral certified since 2021, we are Ecovadis Accredited (Gold, in the top 5% of companies assessed as of 2024) and soon we will be planting a tree for every order placed via our website.

Were Here to Help Guide Inform

Author: Alice Jeavons

Springpack is a UK packaging company delivering sustainable solutions that empower customers. We prioritise exceptional service, building strong relationships and developing innovative packaging solutions tailored to unique needs. Sustainability drives us, from eco-friendly materials to reusable practices minimising waste and emissions. As a family-run business, we’ve grown from humble beginnings to industry forerunners. Our passion lies in making a positive impact in our community and the lives of customers, employees, and stakeholders through outstanding service that exceeds expectations.