Our technology

The product is placed onto a defined tray. The shape, the dimensions or the heights of the product do not matter. The important thing is that it fits the size of the provided shipping box. The automatic feed is used to vertically wrap both - the tray and the product - with the special stretch film. The product is firmly clamped onto the corrugated board format and can be securely shipped in a box.

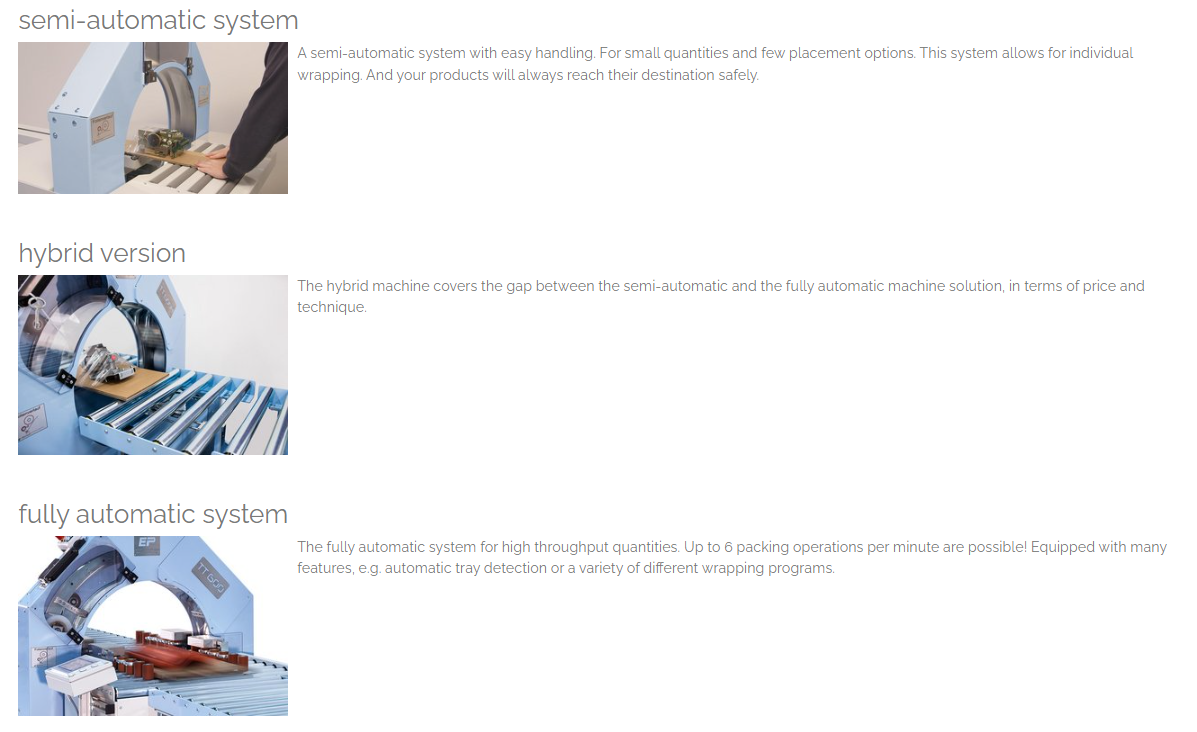

This tray packaging machine ensures perfect product protection, high-speed packaging and low costs. This easy-to-operate machine offers maximum flexibility for small and large product lines. The packaging process still remains the same even for constantly changing products with different heights and weights of up to 160 kg. And the best of it : You reduce the amount of packaging sizes, storage space and time. Filling and cushioning materials are no longer required.

Typical shipped goods include gears, pumps, motors, gear wheels, drives, light- and heavy-weight replacement parts of all types, as well as sensitive machine components from the entire field of process measuring and control technology.

How does the concept work?

Our team develops the sizes you require based on your daily packaging tasks. Furthermore, the new standard program without tool costs can be used. Once the packages have been checked and found to be in perfect condition, we‘re ready to start. You enter into a supply contract for the quantity you require. Then, Emba-Protec will supply you with the wrapping machine, including detailed instructions. All necessary packaging components (trays, film, shipping cartons) are supplied to you on call off. You only pay a fixed set price per packaging supplied. We, of course, will assist you with any queries and wishes for modification. This is part of our customer service.

Your advantages

Packaging sizes are standardised and immediately available

No tool costs

Significant reduction of packaging times / costs

Packaging in random sequence is possible

For products weighing between 0.1 and 160 kg !

No other filling and cushioning materials are required

Best possible product protection during shipping

Reduction of storage costs due to small on-call batches